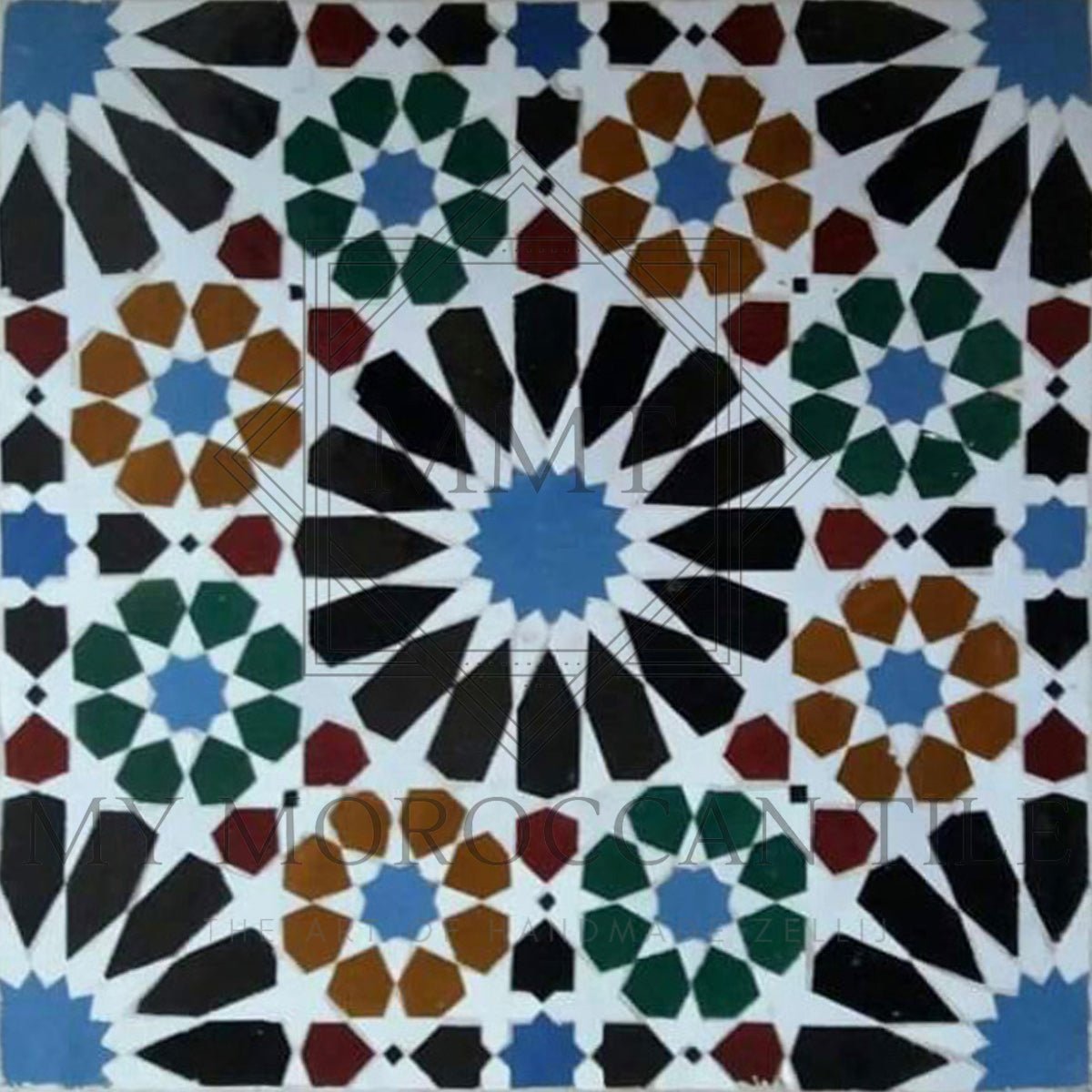

Alhambra Mosaic Tile 16-1

Description: Hand cut and assembled sixteen pointed star Moroccan Mosaic Tile

History: Mosaic inspired from a wainscot mosaic in the Palacios Nazaríes section of the Alhambra.

Applications: kitchens backsplash, bathroom wainscot, wall niches, door frames, floor inserts. Use alone or combine with one of our mosaic borders. Very well suited for wet areas floors and walls.

Sizes: Assembled to size and ships in smaller interlocking sections. Thickness is 5/8"

Price: Per square foot

Color: As Shown or, custom colors

Available in all our standard colors click here to view color palette

Samples: You may order samples via our contact page

Minimum Order: 10 square feet minimum order required

Timeline: 4 to 6 weeks depending on quantity

Returns: This product will be made especially for you. Once order has been place, we cannot accept returns, refunds or exchanges

This product is 100% handmade in Morocco

Ordering Information

Samples Experience the quality firsthand. Order samples via our sample request page before committing to your project.

Minimum Order 10 square feet

Production Timeline4–6 weeks (depending on order size)Your tiles are made to order in Fez, ensuring every piece is crafted specifically for your project.

Investment Pricing Priced per square foot. Select your measurement preference above.

Shipping & Delivery

All orders ship directly from our artisan workshop in Fez, Morocco. We offer flexible shipping options:

Complimentary FOB Airport Delivery Orders 50–250 sq ft receive complimentary freight to your nearest international airport. Simply arrange customs clearance and final delivery.

Door-to-Door Service: Orders up to–250 sq ft. 5–10 days (fees apply)

Complimentary Maritime Freight Larger Projects 6 weeks+ Orders over 250 square feet

Your design consultant will provide detailed shipping guidance based on your project timeline and location.

Made-to-Order Commitment

Because each tile or mosaic is handcrafted specifically for you, we cannot accept returns, refunds, or exchanges once production begins. This exclusivity ensures that your installation is truly one of a kind.

Comprehensive Tile Care and Maintenance Guide

My Moroccan Tile - Preserving Centuries of

Craftsmanship

Introduction

Your authentic

Moroccan tiles represent centuries-old craftsmanship from artisans in Fez,

Morocco. Unlike mass-produced tiles, each piece is handcrafted with slight

variations that make it unique. This guide will help you preserve your

investment and maintain the beauty of your tiles for generations.

Moroccan Zellige Tile Care

Understanding Zellige

Zellige tiles are handcrafted using

traditional methods, resulting in variations in thickness, glaze density, and

porosity. This authenticity requires specific care protocols to maintain their

beauty.

Initial Sealing (Critical First Step)

Timing: Seal

zellige tiles 24-48 hours after grout has fully cured.

Product: Use a

penetrating sealer specifically designed for natural stone and porous tiles

(not a topical sealer).

Application:

·

Apply two coats, allowing 4-6 hours between

coats

·

Wipe excess sealer from surface immediately

·

Allow 24 hours to cure before use

Resealing Schedule:

·

High-traffic areas: Every 1-2 years

·

Low-traffic areas: Every 3-4 years

Daily and Weekly Cleaning

Daily: Sweep or vacuum

with a soft brush attachment to remove grit and debris that can scratch the

glaze.

Weekly: Damp mop with

warm water only, or water with a pH-neutral cleaner (pH 7). Always dry the

surface with a soft cloth after wet cleaning to prevent water spots.

What to AVOID

·

Acidic cleaners: Vinegar, lemon juice, or

any cleaner with citric acid will etch the glaze

·

Alkaline cleaners: Bleach, ammonia, or

harsh degreasers can discolor the glaze

·

Abrasive tools: Steel wool, scouring

pads, or abrasive powders will scratch the surface

·

Steam cleaners: Excessive heat can cause

glaze crazing (fine cracks)

Stain Treatment for Zellige

Oil-based stains (cooking

oil, grease): Apply a poultice made from baking soda and water, let sit for

24 hours, then rinse.

Organic stains (coffee,

wine): Apply hydrogen peroxide (3%) for 10-15 minutes, then rinse

thoroughly.

Hard water deposits:

Mix equal parts water and pH-neutral cleaner, apply with soft cloth.

Terracotta Tile Maintenance

Understanding Terracotta

Your terracotta collection (Terra

Floors, Talia, Bijmat, Octa, Star & Cross, and Hexa) represents unglazed

clay tiles. These are more porous than zellige and require intensive initial

treatment and ongoing maintenance.

Pre-Installation Treatment (For

Contractors/Installers)

Pre-sealing:

Apply a penetrating sealer to all terracotta tiles BEFORE grouting to prevent

grout from permanently staining unsealed terracotta.

Curing time:

Allow 48 hours for sealer to cure before grouting.

Post-Installation Sealing Protocol

After installation and

grout curing (7-10 days):

1.

Deep clean: Remove all grout haze and

construction debris with pH-neutral cleaner

2.

First seal coat: Apply penetrating

sealer, allow to absorb (15-20 minutes)

3.

Second coat: Apply within 1 hour of first

coat

4.

Third coat: Apply 24 hours after second

coat

5.

Optional finish coat: For high-traffic

areas, apply a topical sealer for added protection

Routine Terracotta Maintenance

·

Daily: Sweep or vacuum to remove abrasive

dirt

·

Weekly: Damp mop with pH-neutral cleaner

diluted in warm water

·

Monthly: Apply a maintenance coat of

sealer in high-traffic areas

·

Annually: Strip and reseal entire floor

Understanding Terracotta Patina

Terracotta develops a

patina over time—this is normal and desirable in authentic handcrafted tiles:

·

Color deepening: Terracotta naturally

darkens with age and use

·

Wear patterns: High-traffic areas will

show more patina, adding character

·

Uneven aging: Different tiles may age at

different rates due to clay variation

For clients who prefer a

more uniform appearance, more frequent resealing (every 6 months) can slow

patina development.

Terracotta Stain Removal

Fresh spills: Blot

immediately (never wipe, which spreads the stain).

Oil stains: Poultice with

diatomaceous earth or talcum powder for 24-48 hours.

Deep stains: May require

professional restoration or spot re-sealing after treatment.

Hand-Painted Tile Preservation

Understanding Hand-Painted Surfaces

Hand-painted tiles

feature artisan-applied designs that require gentle care to preserve the

painted surface.

Cleaning Hand-Painted Tiles

·

Frequency: Clean only when visibly dirty

(over-cleaning causes unnecessary wear)

·

Method: Soft microfiber cloth dampened

with warm water

·

Pressure: Light touch only—never scrub

painted surfaces

·

Drying: Immediate drying with a separate

clean cloth

Decorative vs. Functional

Applications

Decorative

applications (wall accents, backsplashes with minimal exposure):

·

Minimal sealing needed

·

Dust with dry microfiber cloth monthly

·

Spot clean as needed

Functional

applications (kitchen backsplashes, bathroom walls):

·

Apply two coats of penetrating sealer

·

Reseal annually

·

Clean weekly with pH-neutral cleaner

Long-Term Protection

·

UV exposure: Hand-painted colors can fade

in direct sunlight; consider window treatments

·

Chemical exposure: Keep harsh cleaners,

perfumes, and aerosols away from painted surfaces

·

Physical protection: Use trivets,

coasters, and cutting boards to prevent direct contact

Mosaic Tile Care

Understanding Mosaic Construction

Custom mosaics have more

grout lines per square foot than standard tiles, making grout maintenance the

primary care concern.

Initial

Grout Sealing

After grout cures (7-10 days):

1.

Clean grout lines thoroughly with pH-neutral

cleaner

2.

Apply grout sealer with small brush or

applicator bottle

3.

Wipe excess sealer from tile surfaces

immediately

4.

Allow 24 hours to cure

5.

Apply second coat

Routine Mosaic Cleaning

·

Daily: Wipe down with damp cloth

(especially in bathrooms and kitchens)

·

Weekly: Clean with pH-neutral cleaner,

paying attention to grout lines

·

Monthly: Inspect grout for discoloration

or deterioration

·

Annually: Reseal grout lines

Grout

Line Maintenance

Discoloration: Usually from

inadequate sealing or using colored cleaning products.

Cracking: Can indicate

substrate movement; address structural issues before regrouting.

Mold/mildew: Indicates

moisture problems; improve ventilation and reseal.

Cleaning Grout Without Damaging

Tiles

·

Use a soft-bristled toothbrush for grout lines

·

Never use grout cleaning products that contain

bleach or acids

·

For stubborn grout stains: paste of baking soda

and water, gentle scrubbing

·

Rinse thoroughly and dry completely

Troubleshooting Common Issues

Efflorescence (White Powdery Residue)

What it is:

Salt deposits that migrate from the tile body or substrate to the surface.

How to address:

1.

Allow tiles to fully dry

2.

Brush off powder with soft brush

3.

Clean with pH-neutral cleaner

4.

If persistent, use an efflorescence remover

designed for natural stone

5.

Ensure proper sealing to prevent recurrence

Grout Haze

Prevention: Pre-seal porous tiles before

grouting.

Removal:

· For

fresh haze (within 24 hours): Damp sponge with frequent rinsing

· For

dried haze: pH-neutral grout haze remover

· For

stubborn haze on terracotta: May require professional restoration

Crazing (Fine Surface Cracks)

Causes: Thermal shock,

substrate movement, or natural aging of handmade tiles.

Is it a problem?

Usually cosmetic only; if cracks are deep or widening, consult installer.

Management: Ensure

proper sealing to prevent moisture infiltration.

Lippage (Uneven Tile Surfaces)

What it is: Slight

height differences between adjacent tiles.

Is it a defect?

No—this is characteristic of handcrafted tiles where thickness varies.

Care consideration:

More careful cleaning needed to avoid catching mop edges on raised tiles.

Color Variation

What to expect:

·

Shade variation between tiles is normal and

desirable

·

Color may deepen or lighten with age

·

Different production batches will have variation

This is not a defect: It's proof of

authentic handcrafted production by artisans in Fez, Morocco.

Quick Reference Chart

Tile

Type

Daily

Care

Weekly

Care

Sealing

Frequency

Zellige

Sweep/vacuum

Damp mop,

pH-neutral cleaner

1-4 years

Terracotta

Sweep/vacuum

Damp mop,

pH-neutral cleaner

6-12 months

Hand-Painted

Dust as

needed

Soft damp

cloth

Annually

(functional areas)

Mosaic

Wipe with

damp cloth

Clean with

pH-neutral cleaner

Grout:

Annually

Recommended Products

Safe

Cleaners

·

pH-neutral tile cleaners (pH 7)

·

Warm water

·

Baking soda paste (for spot cleaning)

·

Hydrogen peroxide 3% (for organic stains)

Sealers

·

Penetrating sealers for natural stone and porous

tiles

·

Grout sealers (water-based)

·

Topical sealers (for high-traffic terracotta

only)

Tools

·

Soft-bristled broom or vacuum with brush

attachment

·

Microfiber mop and cloths

·

Soft-bristled toothbrush (for grout lines)

·

Non-abrasive sponges

Professional Support

For

questions about caring for your specific tile installation, or to order

replacement tiles, please contact My Moroccan Tile:

Website:

mymoroccantile.com

International Sites:

France/Belgium: carreauxzellige.com

Morocco: saharadesigns.com

Spain: azulejosmarruecos.com

Follow

us: @mymoroccantile on Instagram, Pinterest, and Twitter

Final Thoughts

Your Moroccan tiles are not just a

surface—they're a piece of living history, handcrafted by skilled artisans

using techniques passed down through generations. With proper care, these tiles

will develop character and beauty that only improves with time, becoming a

treasured feature of your space for decades

Our Artisan Family Our craftsmen work for us in Fez, no middlemen, no mass production. Your purchase supports traditional craftsmanship and preserves centuries-old techniques passed down through generations.

Museum-Quality Standards Holding the prestigious "Zellige de Fès" quality label, our mosaics meet the highest standards of Moroccan artisan certification.

Legacy Creation These aren't just tiles. They're heirlooms that will grace your space for generations, developing character and patina that only authentic handcrafted materials can achieve.

Handmade Moroccan Tile

Our tile is entirely handmade using traditional Moroccan techniques passed down through generations. Each piece is carefully shaped, cut, and glazed by artisans in Fès, the birthplace of authentic Zellij. Holding the “Zellige de Fès” quality label, our collections reflect the highest standard of craftsmanship and authenticity. Every variation in color and texture reveals the human touch behind the work, making each tile a one-of-a-kind creation that embodies the timeless beauty and soul of Moroccan artistry.

The Artisan Story

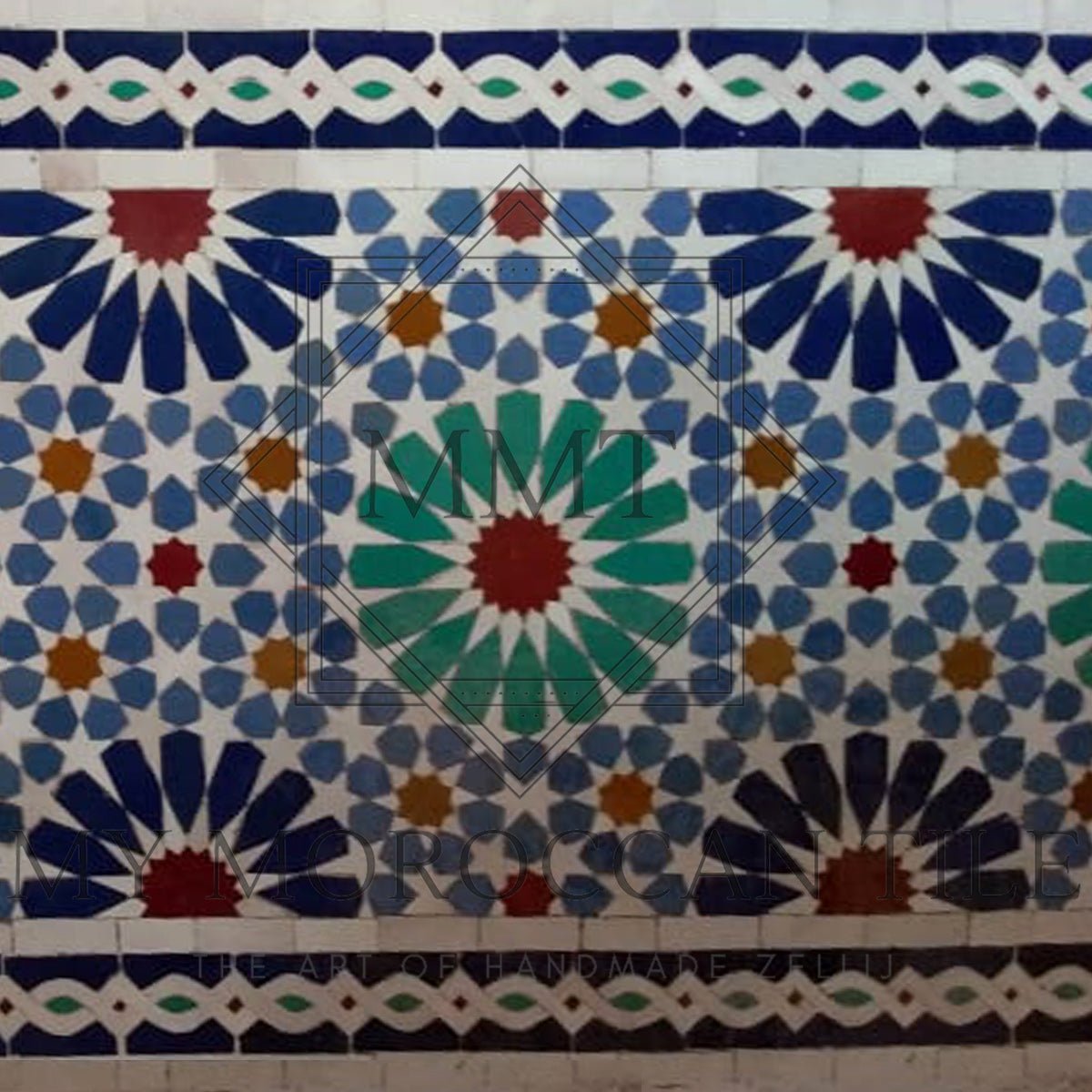

This design celebrates the geometric precision and botanical elegance that define Moroccan craftsmanship. Every tile is shaped by hand, cut with traditional tools, and assembled piece by piece in our Fez workshop—a process that honors generations of artisan knowledge passed down through families.

The result is more than a surface. It's a legacy.

Mosaics assembly

Mosaics made just for you

Experience personalized mosaics tailored to your vision, including custom colors, scale, and precise fitting. Each piece is preassembled and shipped in interlocking sections, designed for effortless installation and grouting. Whether built to your custom measurements or provided in smaller panels of 12"x12" or less, our mosaics ensure a seamless and elegant transformation for your space.